Plastic Injection Molding

Our wide range of injection molding presses offer powerful capabilities and endless possibilities.

We got it all.

Steinwall specializes in custom injection molding of high cosmetic, tight tolerance parts using special injection molding and engineering grade thermoplastic resins. We manufacture parts of many complexities over a wide range of sizes; with press capacities from 30 to 1,750 tons and shot sizes from 1 ounce to 104 ounces.

Automatic aid.

Automation robotics is utilized throughout the facility and aid in 2-shot, insert molding, and in-mold labeling. We support these processes with an internal tool room for mold maintenance, end of arm tooling, and secondary fixtures.

Our Capacity.

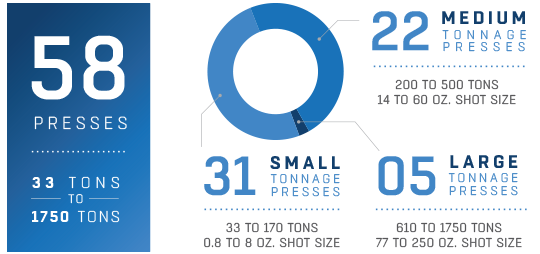

With 58 presses in operation, Steinwall is uniquely positioned to economically manufacture plastic parts ranging in size from under an inch to large parts more than 8 feet wide. Our production flexibility and additional secondary operations make us a reliable vendor partner for customers who need a long term, reliable source for plastic injection molded parts.

Contact Steinwall for your next plastic injection molding project

Looking for a complete list of press tonnages and shot sizes?

Did you know?

We utilize 300 different resins from 30 different material families.

Order our popular

Plastic Materials Matrix

poster FREE!

763.767.7060

1.800.229.9199

1759 116th Avenue

Minneapolis, MN 55448

Follow Us

Services

Company